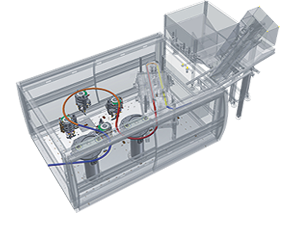

Brau Beviale 2018 is approaching fast! SMI will be waiting for you at the stand 7A-503 to show you the ultra-compact, efficient and ergonomic EBS K ERGON rotary stretch-blow moulder that meets the needs of the “Smart Factory 4.0”.

Available in 2,3 and 4-cavity models, it is the ideal solution for manufacturing PET containers in the output range up to 9,000 bottles/hour and offers all the benefits of the rotary technology.

|

It is ultra-compact!The preform-heating section is integrated with the stretch-blow moulding section into a single module, which is easily accessible thanks to an ergonomic frame equipped with slightly rounded safety doors. |

||

It is efficient and eco-friendly!

The infrared lamps for preform heating, equipped with thermo-reflective panels made of composite material, distribute the heat over the preform uniformly, thus ensuring high-quality bottles and lower energy consumption. |

|

||

|

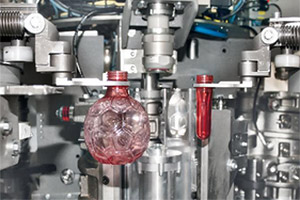

It is precise and flexible!

Stretch-blowing stations are equipped with motorized stretch rods, controlled by digital servo drives (they do not require mechanical cams), ensuring the utmost precision and flexibility of the stretch-blowing process. |

||

It is fast and easy to run!

The format changeover is simple and fast thanks to the MotorNet System® automation and control system, which governs the machine; moreover, the usage of high-performance valves shortens pre-blowing and blowing times. |

|

||

|

An even more compact line!

The new EBS K ERGON is also available in ECOBLOC® configuration, combined with a filling and capping module, in order to achieve high performances at reduced costs in the bottling of beverages and liquid food into containers of up to 3L. |

[youtube https://www.youtube.com/watch?v=BZHqlLfegvE]